Your One-Stop Shop for Finished Parts

Secondary Operations

We take your parts from machined to magnificent. R.F. Mau's comprehensive secondary operations, powered by Haas CNC milling and turning machines and enhanced with robotic precision, add the finishing touches that elevate your products.

From complex milling and turning to precise drilling and tapping, we handle every detail in-house. This integrated approach saves you time, money, and hassle, providing a complete, value-added solution for all your precision machining needs.

Efficiency is built into every step with our advanced secondary operations. Our Haas CNC milling and turning centers, working in concert with robotic automation, create a symphony of precision and speed. This automated approach not only accelerates production but also ensures consistent quality and minimizes handling, resulting in cost savings and faster turnaround times for our customers.

This means faster turnaround times, reduced handling costs, and consistent quality—all under one roof. We keep your project moving forward, seamlessly and efficiently.

Watch this QUICK video

Haas lathes, mills and robotics

Integrating Haas lathes and mills with robotics offers a powerful combination of precision, efficiency, and automation, resulting in numerous benefits:

Increased Productivity as robotics significantly boost productivity by enabling lights-out, unattended operation. Robots can load and unload parts, allowing the Haas machines to run continuously, maximizing throughput and reducing downtime.

Robotic arms provide precise and repeatable part handling, minimizing human error and ensuring consistent quality across large production runs. This reduces variations in finished parts and improves overall product quality.

Reduced Labor Costs

By automating part loading and unloading, robotics reduce the need for manual labor, leading to significant cost savings. This allows human operators to focus on more complex tasks like programming, setup, and quality control.

Faster Turnaround Times

Automated loading and unloading, coupled with continuous machine operation, significantly reduces cycle times and speeds up production. This translates to faster turnaround times for customer orders.

Greater Flexibility

Robots can be easily reprogrammed to handle different parts, providing greater flexibility in production. This allows manufacturers to quickly adapt to changing customer demands and product designs.

Competitive Advantage

The combination of Haas machines and robotics gives manufacturers a competitive edge by enabling us to produce high-quality parts faster, more efficiently, and at a lower cost.

Packaging Materials & Container Styles:

-

Hand Layered

-

Bulk Packing

-

Corrugated - Stapled/Stitched

-

Cell Pack

-

Custom Packaging

Product Types Served:

-

Appliances

-

Batteries

-

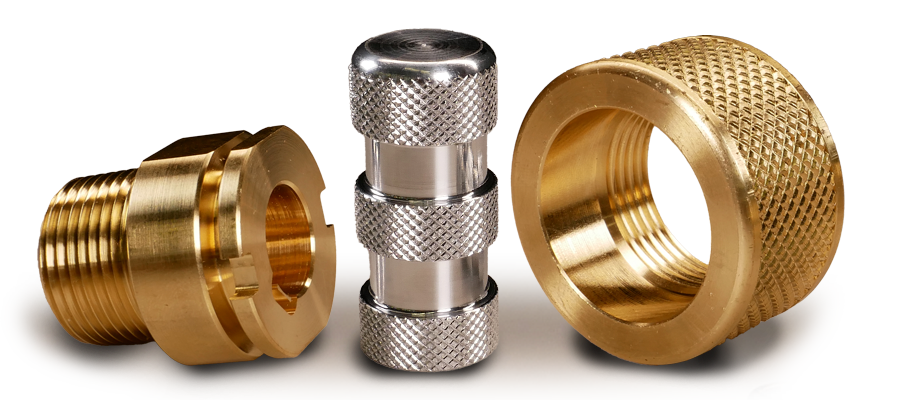

Brass Insert Fittings

-

Compression Fittings

-

Computers

-

Electrical Applications

-

High Voltage Fuse Parts

-

HVAC Fittings

-

Hydraulic Fittings

-

Faucet Parts

-

Insert Fittings

-

Laboratory Faucet Markets

-

Lighting Fixtures

-

Lock Hardware

-

Shower Heads

Custom Finishing Services:

-

High Volume Production Degreasing (Computer Controlled, Automated Process)

-

Deburring

-

Drilling

-

Tapping

Plating Finishes (Outsourced):

-

Black Oxide

-

Brass Plated

-

Chrome

-

Anodizing

-

Nickel Plated

-

Painted

-

Polished

-

Silver Plated

-

Zinc Dichromate