Zero Emission Part Cleaning

Say goodbye to vapor degreasing.

We're not just machining parts; we're engineering a sustainable future. R.F. Mau's cutting-edge IFP vacuum degreasing system is just one example of how we combine technology and environmental responsibility.

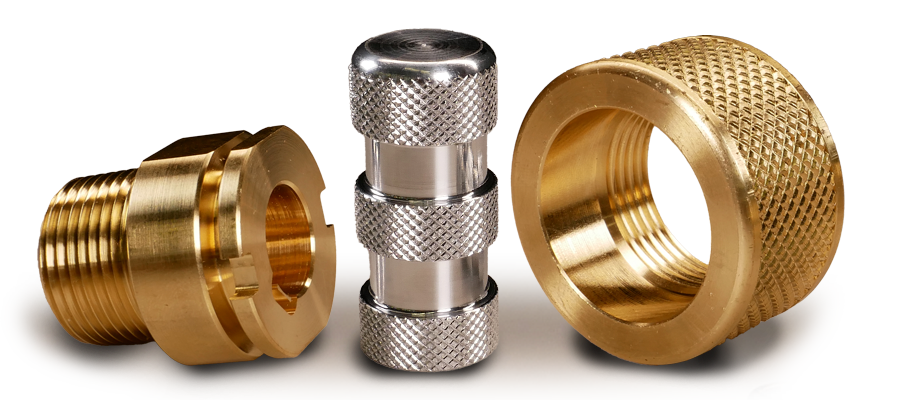

This "green-certified" marvel delivers impeccably clean, dry, and chip-free parts—think jewelry, not just hardware—while eliminating hazardous waste.

Our IFP vacuum degreaser is an industrial parts cleaning system that uses vacuum technology and specialized, often environmentally friendly, solvents to remove contaminants like oils, grease, and chips from manufactured parts. Operating in a sealed chamber under vacuum, the system lowers the solvent's boiling point, allowing for effective cleaning at lower temperatures. Solvent vapors penetrate even complex geometries, dissolving and removing contaminants before a vacuum drying cycle leaves parts clean and dry.

Our IFP systems utilize a closed-loop design, recovering and reusing the solvent to minimize waste and environmental impact. This technology is preferred in industries with strict cleaning requirements and environmental regulations due to its effectiveness, gentle operation, consistent results, and reduced solvent consumption.

Discover the R.F. Mau difference.

Watch this QUICK video

Benefits of vacuum degreasing

Environmentally Friendly

Vacuum degreasing uses environmentally friendly solvents and closed-loop systems, minimizing waste and emissions compared to traditional methods.

Custom Cleaning

Every single part has its own cleaning program that is programmed to the parts geometry. This allows for deep cleaning of complex parts, penetrating intricate geometries and removing contaminants like oils, grease, and chips thoroughly.

Gentle Cleaning

Lower operating temperatures reduce the risk of damage to sensitive parts during the cleaning process.

Dry Parts

The vacuum drying cycle ensures parts are completely dry and ready for use after cleaning, eliminating the need for additional drying steps.

Consistent Results

The controlled vacuum environment and automated processes, combined with the part-specific cleaning programs, provide consistent and repeatable cleaning results, ensuring high quality across batches.